Mining operations rely on equipment that can deliver strength, consistency, and precision under demanding conditions. Selecting the right machinery becomes a critical investment decision when planning large-scale extraction or exploration work. For companies looking to buy a rig for mining, performance-driven drilling rigs offer the reliability needed to maintain productivity while minimizing operational disruptions. Built to handle extreme loads and challenging terrain, modern drilling rigs play a central role in advancing efficient mining operations.

1. Engineered Strength for Mining Environments

High-performance drilling rigs are designed to withstand harsh mining conditions while maintaining stable output across long operating cycles.

- Reinforced structural design

Heavy-duty frames provide stability during drilling, even in rocky or uneven ground. This strength reduces vibration, improves bore accuracy, and protects internal components from premature wear. - Durability under continuous operation

Mining projects often demand extended working hours. Rigs built for endurance maintain performance without frequent breakdowns, ensuring uninterrupted progress and reduced maintenance costs. - Resistance to environmental stress

Exposure to dust, heat, and moisture is common on mining sites. Advanced materials and protective finishes help preserve rig functionality in challenging environments.

2. Power Systems Built for Consistent Output

Reliable power delivery is essential for drilling through dense geological formations commonly found in mining zones.

- High-torque engine capabilities

Powerful engines generate the force required to penetrate hard rock layers efficiently. Consistent torque output supports steady drilling speeds and minimizes equipment strain. - Optimized hydraulic performance

Modern hydraulic systems provide precise control over drilling pressure. This allows operators to adapt quickly to changing ground conditions while preserving mechanical efficiency. - Fuel efficiency and operational balance

Efficient power systems reduce fuel consumption without compromising output, helping control operational costs while maintaining high productivity levels.

3. Precision Control for Operational Accuracy

Accurate drilling directly impacts safety, material recovery, and long-term mine development planning.

- Advanced control interfaces

Operator-friendly panels allow real-time monitoring of drilling parameters. Clear feedback enables accurate depth control and improved drilling consistency. - Improved bore alignment

Precision-guided drilling minimizes deviations that can affect ore extraction efficiency. Accurate bore placement supports better material yield and structural planning. - Reduced material waste

Controlled drilling limits unnecessary excavation, reducing waste handling and site disruption while improving overall efficiency.

4. Adaptability Across Mining Applications

Modern mining projects require equipment that can perform across different operational requirements.

- Versatile drilling configurations

High-performance rigs can support various drilling methods, making them suitable for exploration, extraction, and site development work. - Scalable performance settings

Adjustable speed and pressure controls allow rigs to adapt to different rock densities and project depths without compromising safety. - Compatibility with mining workflows

Flexible rig designs integrate smoothly into existing mining operations, enhancing productivity without operational delays.

Conclusion

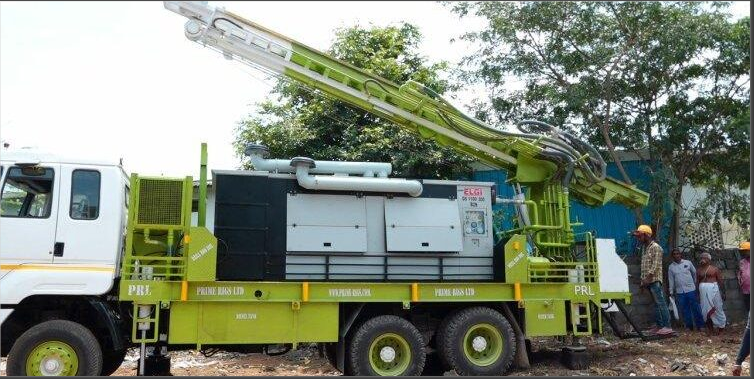

High-performance drilling rigs have become essential assets in modern mining operations, offering durability, precision, and power where it matters most. Their ability to deliver consistent output, adapt to complex conditions, and reduce downtime makes them a strategic investment for long-term success. Companies such as Prime Rigs support mining professionals by providing dependable drilling solutions designed for performance, reliability, and operational efficiency, helping projects move forward with confidence and control.